Level Measurement in the Electric Arc Furnace (EAF)

Reliable non-contact measurement for safe and ffficient Steelmaking Accurate level measurement in the Electric Arc Furnace (EAF) is a critical requirement for safe, stable, and

mecorad offers radar-based in-line measurement & optimization for the steel industry and hot metals forming of non-ferrous metals. Whether you are dealing with continuous casting, rolling of flats, longs or heavyplates – our solutions and products can support the reduction of yield loss. Moreover, mecorad´s radar measurement solutions for the steel industry can connect your production facilities internally & along their value chain. Take a step into a more sustainable production world.

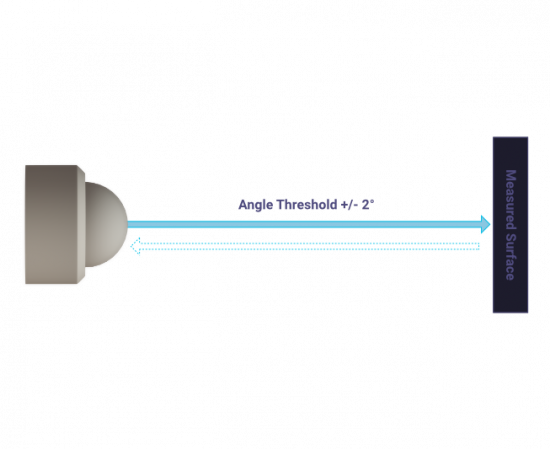

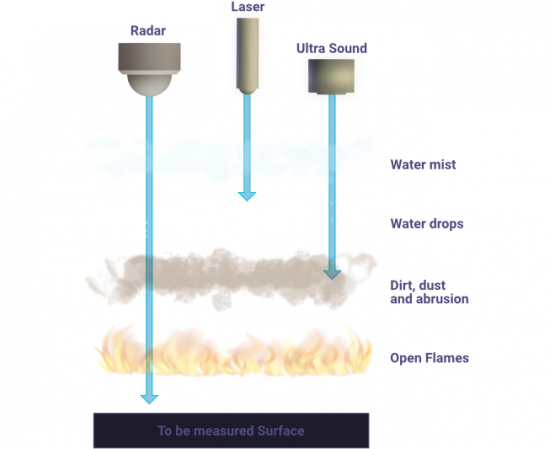

Radar measurement is based on non-harmful electromagnetic waves: The sensor emits a high-frequency signal that moves targeted directly and at the speed of light. For optimal results, a straight alignment of the radar sensor to the target object is necessary. Hitting the object, the signal is reflected at the same angle of incidence. By receiving the reflected signal and analyzing it´s specifics, we can detect metallic objects, determine distances or positions, even of moving objects.

Radar is even suitable for harshest environments: The electromagnetic waves are insensitive to adverse conditions such as high temperatures, polluted air, smoke or fog. Radar provides correct signals at open flames or glowing metals, where average red laser systems fail.

Our solutions measure with high precision: they determine the width of objects with up to 50 micrometer accuracy, thickness with up to 200 micrometer. Thanks to protective housing and further compensation options, the values remain precise and reliable even under extreme conditions, such as above the melt or in continuous casting.

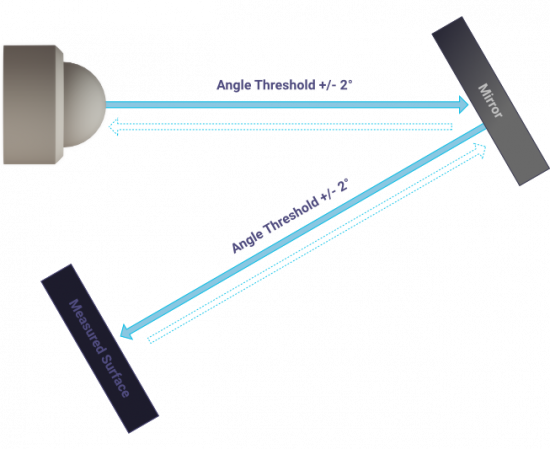

There are areas where a straight alignment of sensor to target is not possible. To enable measurements even in these areas, mirrors or reflective surfaces can be used to direct the signal.

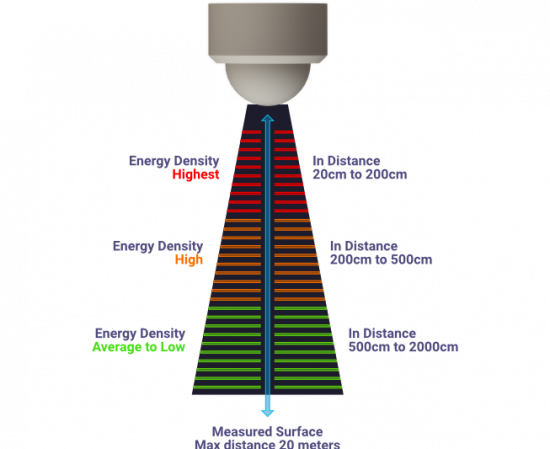

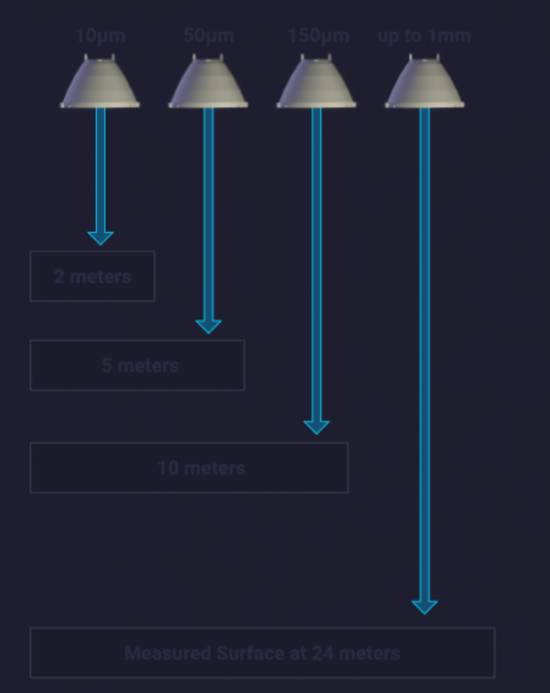

Radar measurements are possible over long distances. However, it is important to know that the signal strength decreases over distance, due to various reasons, such as atmospheric absorption, beam-shape losses or beamwidth factors. mecorad compensates these losses to guarantee a stable result in a range from 200 mm up to 5000 mm from the target object.

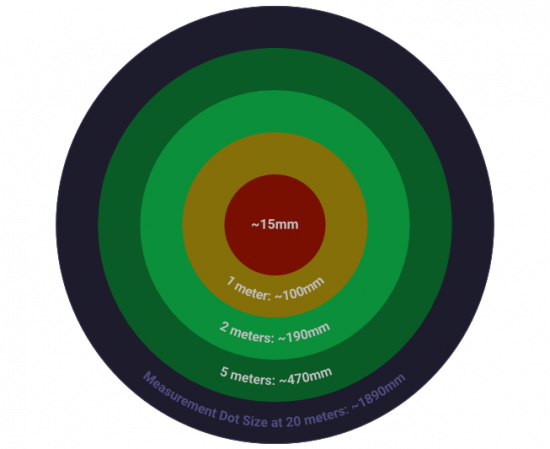

Due to the slightly conical propagation of the radar beam, the signal hits a measuring spot at the target object. The size of the spot depends on the distance of the object and the opening angle of the emitting lens. To get more precise results and clear signals, a smal spot is necessary.

The wtl series is the advanced solution for measuring object geometries, like width, thickness or length in-line in real time. Achieve micrometer measurement accuracy up to 200 micron in width, or 50 micron in thickness, even where the conventional optical or laser sensor technologies reach their limits.

We offer single sensor products for different use cases. Find out how our sensors can improve your distance measurement, level and freeboard determination as well as hot and cold metal detection for changing material parameters. Our product development takes place under plant conditions.

Reliable non-contact measurement for safe and ffficient Steelmaking Accurate level measurement in the Electric Arc Furnace (EAF) is a critical requirement for safe, stable, and

Radar technology is transforming the way foundries understand and control their casting processes. At the Barbaratagung on November 27, we will showcase how real-time, contactless

At mecorad, we are committed to pushing the boundaries of precision and transparency in industrial processes. One of our latest achievements marks a decisive step

Do you want to find out how our products will improve your processes?

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |