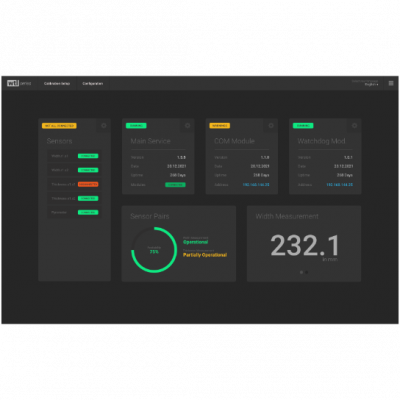

In-line intervention for casting processes

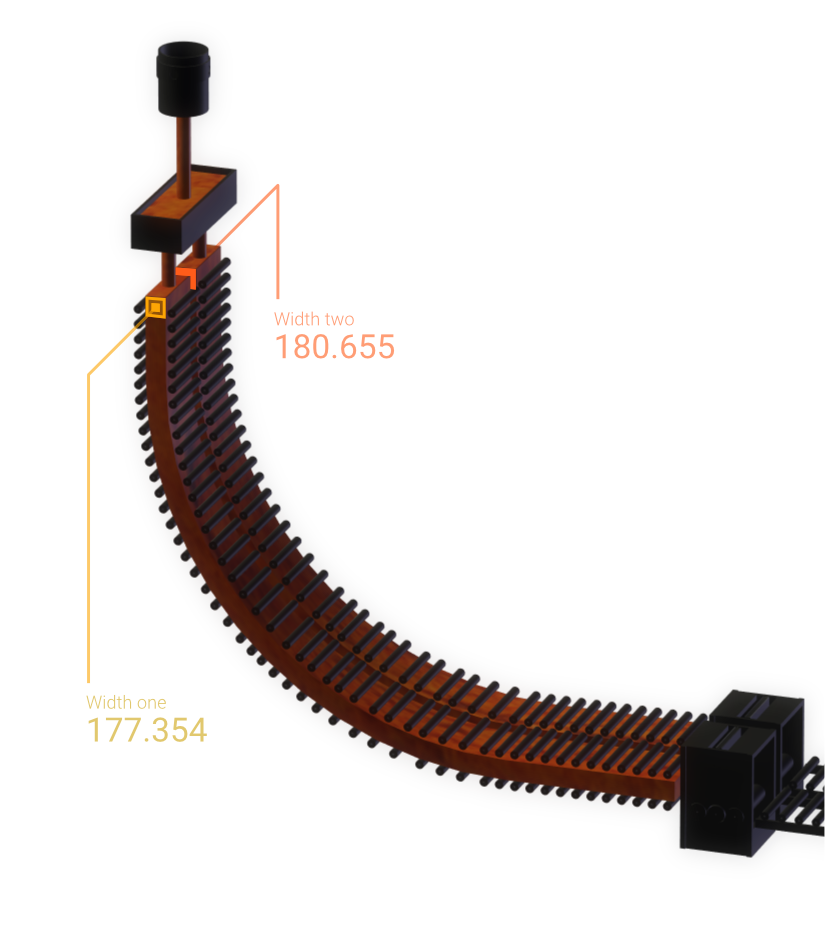

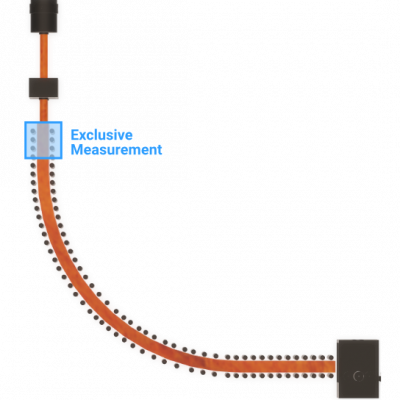

While existing systems only check the dimensional accuracy at the end of the straightening zone, mecorad´s wtl series for continuous casting provides precise and robust geometrical information of slab casting processes directly from below the mold exit in the cooling zone.