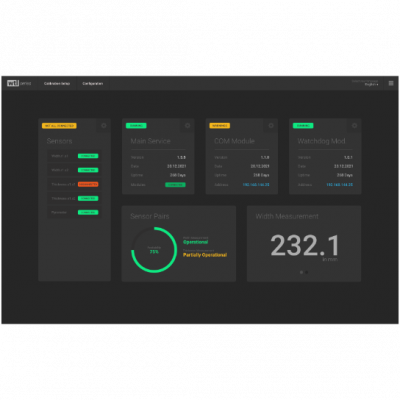

It is not a measurement system. It's a solution.

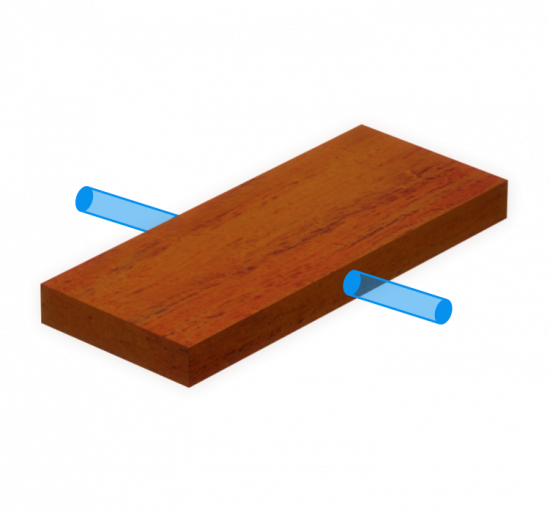

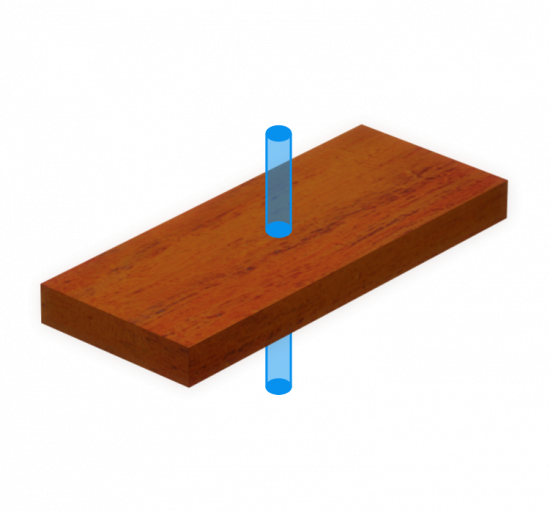

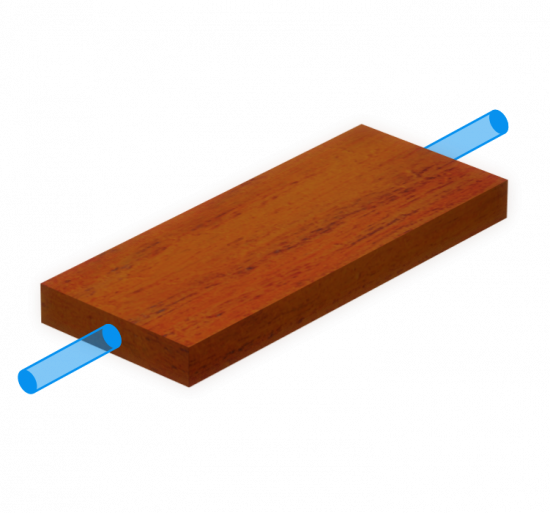

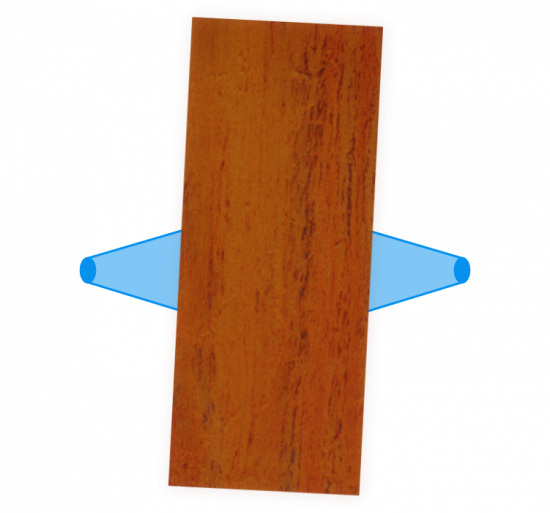

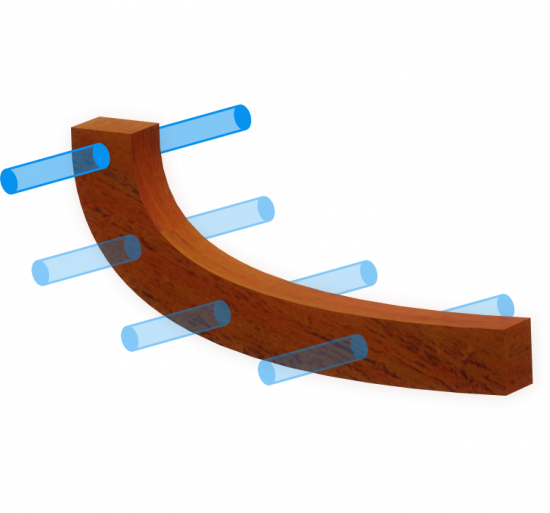

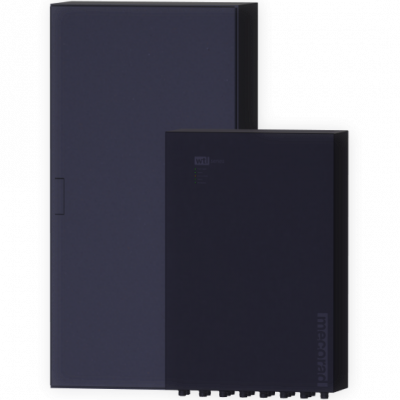

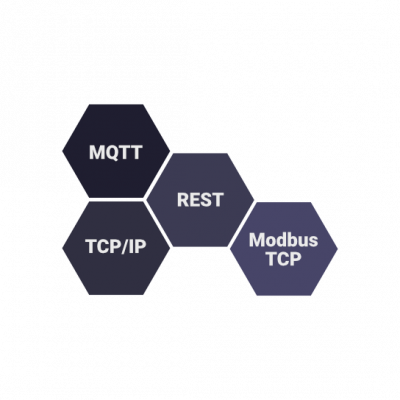

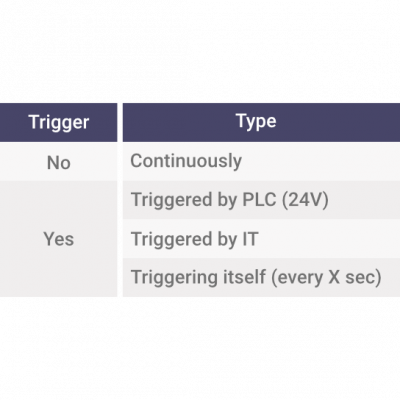

The wtl series delivers precise and robust information from the toughest process stages in continuous casting and hot rolling of flats, longs or heavy plates. The software running the solution distributes digital information to any production level for a flexible production and beyond. Know your production results and perform precise in-line interventions for improved yield.